Universal Signal Conditioners / Converters

PR Electronics Universal Signal Conditioners and Signal Converters offer the highest accuracy and reliability for the Industrial market.

Used mainly in the Oil & Gas, Pharmaceutical, Water and Waste Water, Cement and Process Control Industries, these transmitters offer superior quality with certain series’ offering the unique clip-on display programmer, as well as a 5 year warranty for all products.

For the complete range of Signal Conditioners, or application assistance please contact us.

Products

- Input: Universal RTD or Thermocouple, Volt, mA, Resistance, Potentiometer

- 2-Wire Loop Supply for Loop Powered Transmitters

- Output: mA, Volts, 2 x Programmable Relay Dry Contacts

- Power Supply: Universal 23-250AC, or 20-300VDC

- Optional PR-4501 Clip-On Display for Setup, and I/O Viewing

- Optional PR-4511 Modbus Display Programmer

- Optional PR-4512 Bluetooth Display Programmer for remote configuration

- 2.3KV Galvanic 3-Way Isolation (Input, Output & Supply)

- UL & FM Approved for Class 1, Div 2

- Convert, Scale, and Calibrate most process analog signals

- Manual Simulation of Output for Commissioning or Trouble Shooting

- 3 x Way Galvanic Isolation Eliminates Ground Loop Faults, and protects instruments and electronics

- Manual Override to keep processes running in the event of a system failure

- 2 x Alarm Relay Contacts

- Easy to use operator interface, for viewing Input, Output, and Status conditions

- Secure Password protected

- Input: 2 x Universal RTD, or TC, Volt, Bipolar mV, mA, Resistance, Potentiometer

- 2-Wire Loop Supply for Loop Powered Transmitters

- Output: 2 x mA (Active or Passive), or Volts

- Custom Sensor Linearization

- Power Supply: Universal 23-250AC, or 20-300VDC

- 3.75KV Galvanic 3-Way Isolation (Input, Output & Supply)

- Redundancy Temperature measurement with 2 input signals

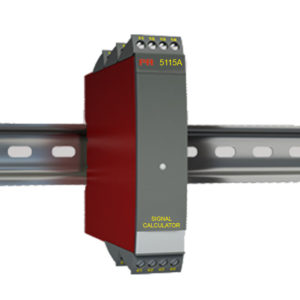

- Signal calculator with the four arithmetical operations

- Can function as a signal splitter

- Requires PR-5909 Programmer & Free Software for setup

- Convert, Scale, and Calibrate most process analog signals

- Dual Channel Input with multi-program functionality

- 3 x Way Galvanic Isolation Eliminates Ground Loop Faults, and protects instruments and electronics

- Critical Process monitoring

- Can be used for signal splitting

Accessories

- Modification of operational parameters on system 4000 and 9000 series devices

- Calibration, scaling, and simulation (manual over-ride) features

- Fixed display shows input, output, alarms, and process status

- Password protection

- Scrolling help text in 7 languages

- Detachable – clips on to the front of the device mounted in the process

- Convert, Scale, Calibrate, and Manual Over-ride functions

- Process Display for any Pressure, Level, Temperature, Speed etc.

- Critical Process monitoring

- Password protected, and removable

- The PR-4511 has full PR-4501 programming functionality, and diagnostics handling

- Modbus RTU via a serial RS-485 communication

- Multidrop half-duplex connection via shielded RJ45 connector

- High safe galvanic isolation of 2.5 kVAC

- Modbus parameters such as address, baud rate, stop bit(s), and parity bit are configured from the 4511 display, which also stores parameters.

- Convert, Scale, Calibrate, and Manual Over-ride functions

- Remotely monitor your processes on-line via a Modbus to Ethernet/TCP gateway

- Process Display for any Pressure, Level, Temperature, Speed etc.

- Critical Process monitoring

- Password protected, and removable

- Bluetooth communication between PR 4000 and 9000 devices and iOS/Android devices

- Access your processes without opening cabinets, or in difficult to reach locations

- Live monitoring of process values

- Diagnostics on compatible smart devices or directly on the PR-4512

- Advanced data logging and event logging using the built-in real-time clock

- Remotely monitor, control, and access processes from your smart device

- Program devices via Bluetooth using an iOS/Android device

- Use the free PPS app (PR Process Supervisor).

- Use PPS data for preventive maintenance.

- All logged data can be exported in .csv format, for advanced data analysis off-site.

- On-site analysis of real-time process data on an iOS/Android compatible device.

- Off-site analysis of historic process data on a PC using PReset.