With water analyzer systems, it may be challenging to accurately calibrate the analyzer due to the process ppm changing from the time the sample is taken, to the time the analyzer is actually calibrated.

For example: the analyzer is reading 1.05 ppm at the time the sample is taken. Then by the time the sample is confirmed by a 3rd party measurement (hand-held or lab test) to be say 1.3 ppm, then by the time the operator comes to calibrate the analyzer, the reading might be lower or higher than 1.05 ppm, so calibrating the controller to 1.3 ppm based on the analyzer initially 1.05 ppm would now be incorrect.

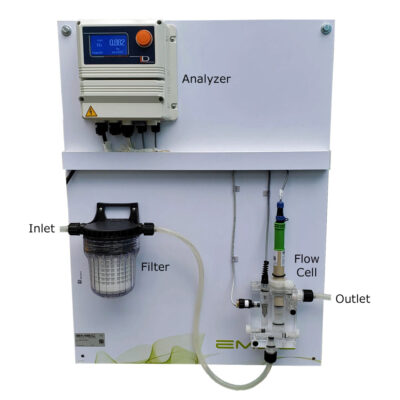

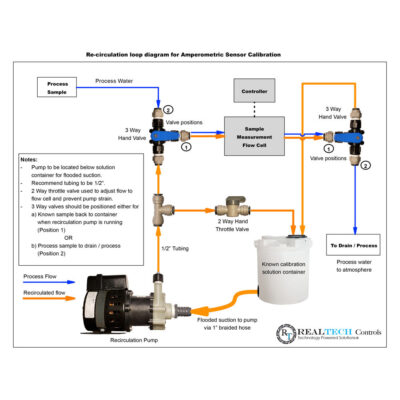

To solve this problem, we can provide a closed-loop water sample to the flow cell which would provide a stable sample to be calibrated correctly. Isolation valves are used to direct the water flow in a recirculated loop to the flow cell, while isolating the incoming process water. The system consists of a re-circulation pump, valves, fittings, and tubing to suit. The container would be supplied by the customer to suit the size and location of the process.

Download the re-circulation block diagram here